Laser Shutters for Systems

Versatile, durable and fail-safe shutter designs for laser applications

Laser systems often require blocking devices to avoid injury from accidental exposure. Brandstrom Instruments rotary solenoid shutters are frequently used in safety applications but are also used to redirect, filter or attenuate laser light.

Customizable laser beam shutter solutions for your unique requirements.

We offer reflective finishes, innovative blade shapes, hall effect sensors, ND filters and many more features not found in off-the-shelf products. Our rotary drive shutters are used in commercial, scientific, medical and defense laser applications including:

- Neutral density (ND)/ optical density (OD) filter positioning

- General laser safety

- Laser surgery

- Target acquisition

- Fiber optics

Defense Application Spotlight: Future Laser System Programs

Brandstrom has ongoing advanced engineering efforts to address the shutter requirements of future laser system programs such as Joint Effects Targeting System (JETS). JETS is the next generation modular day/night all-weather use precision Laser Target Locating System for threat targets and designating threat targets for engagement by Global Position System (GPS) precision laser guided munitions for a variety of Army and Joint weapons.

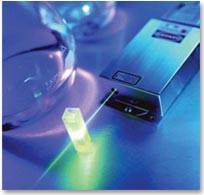

Brandstrom Instruments’ optical shutters are commonly used in laser safety applications.

Brandstrom Instruments’ optical shutters are commonly used in laser safety applications.

Contact an Engineer

Our laser shutters provide advance laser program designers with proven value added features anda low risk technical approach. Use of existing shutters ensures compliance or exceeds critical system performance parameters. Commonality features transition the existing battlefield-proven performance, high reliability and streamlined logistics support to your new product.

Brandstrom Instruments can provide innovative solutions for your products, too. Please contact us to discuss your specific laser shutter application.

Laser Blocking Shutters

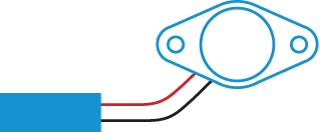

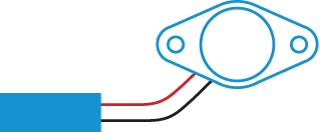

We design custom miniature rotary solenoid assemblies for laser blocker shutters, laser safety shutters, ND (neutral density) filter actuators, and front surface mirror positioning. Our Optical Beam Shutters use a rotary, electro-mechanical actuator to provide inherent “fail-safe” operation.

Examples of rotary drive laser shutters used for laser blocking, deflection,

positioning and restriction

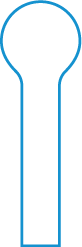

- A0536-2 Shutter

- Self-restoring

- Blade: ø .2″

- Rotation: 32.5° CCW

- Solenoid: ø 3/8″

- Download Drawing

- Download 3D PDF

- Request Pricing

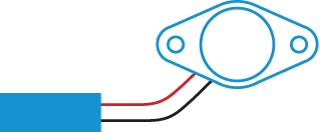

- A1122 Reflecting Shutter

- Self Restoring

- Blade: .722″ x .625″

- Rotation: 45° CW

- Solenoid: ø 7/16″

- Download Drawing

- Download 3D PDF

- Request Pricing

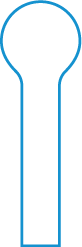

- A1031 Shutter

- Bi-stable

- Blade: ø .196″

- Rotation: 29.0° CCW

- Solenoid: ø 1/2″

- Download Drawing

- Download 3D PDF

- Request Pricing

- A1007 Positioning Shutter

- Self-restoring

- Blade: ø 1″

- Rotation: 60° CCW

- Solenoid: ø 7/16″

- Download Drawing

- Download 3D PDF

- Request Pricing

Our laser shutters block apertures from 1mm to several inches in diameter. We can customize power, travel, mountings, blade dimensions, hall effect magnets and many other features to your exact specifications.

Blade Type

- Flat

- Cylindrical

- Pocket Machined

- Profiled

Blade Material

- Carbon Fiber

- Aluminum

- Stainless Steel

- Filter Materials

Blade Finish

- Black Anodized

- Electroless Nickel

- Diffuse Gold Plate

- Painted

Coatings

- Thermal Absorptive

- Low Emissivity

- Specialty coatings

Rotary Solenoid Configurations

All rotary solenoids manufactured by Brandstrom Instruments operate based on the principle of a spring-free, electromagnetic system. Mechanical and electrical operating parameters can differ depending upon application, but all rotary solenoids conform to one of the three configurations described below:

Bi-Stable Solenoid

Click & release the power button to test.

When the Bi-stable solenoid is energized with a pulse, the shutter rotates from the start position to the secondary position. It will remain magnetically latched in the secondary position until an opposite polarity pulse is applied, returning the shutter to its starting position

Self-Restoring Solenoid

Click & hold the power button to test.

The solenoid is magnetically latched in its home position until it is energized, then the shutter will rotate to the secondary position and remain there until power is removed, allowing it to return to the home position.

Self-Restoring 3 Position Solenoid

Click & hold the positive or negative power buttons to test.

The solenoid is magnetically balanced in a center position until it is energized; then the shutter rotates to position 2 and remains there until power is removed, returning the shutter to the center position. A reverse polarity pulse is applied to rotate the shutter in the opposite direction to position 3 where it will remain until power is removed, returning the shutter to the center position once again.